Features

Warehouse & Logistics Consultant

To share our experience and expertise.

Warehouse Design

To design and optimize warehouse space.

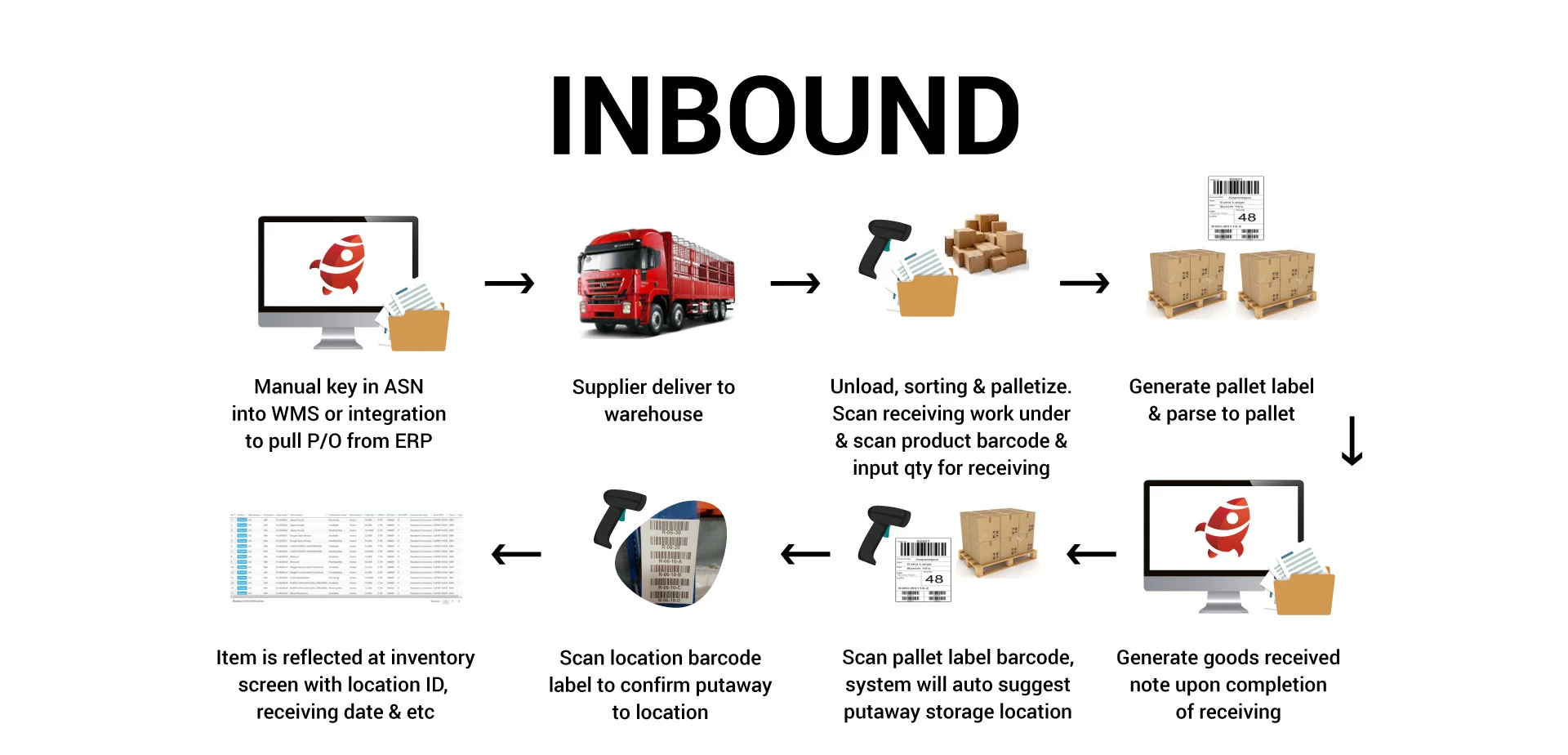

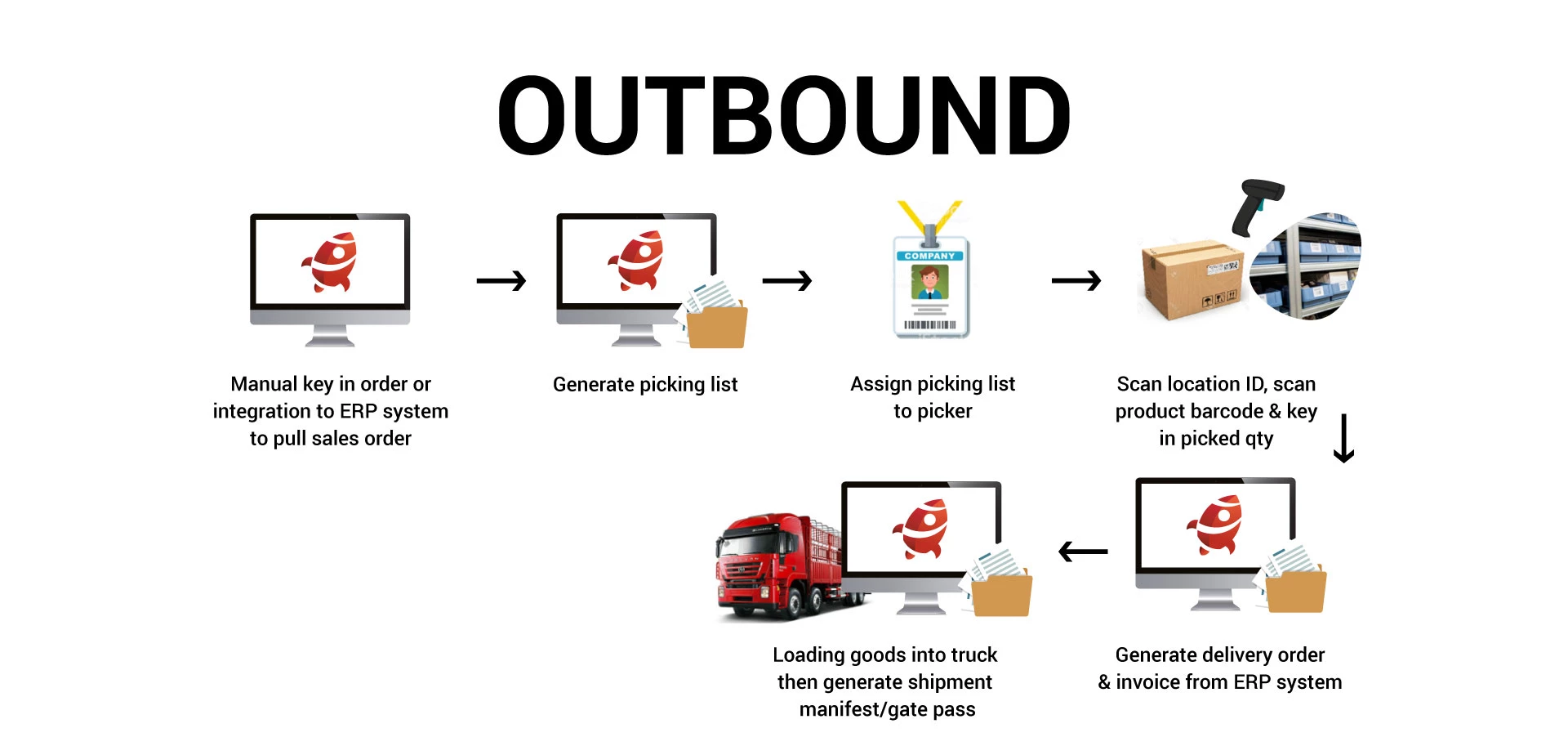

System Setup

To configure system process flow, system customization & host integration.

Analysis & Reporting

To analyse warehouse performance and KPI reporting.

Requirement Study/ Analysis

To analyse a combination of problems and opportunities needed as an input for system implementation.

System Design & Testing

A process to define the system architecture, modules, interfaces and data to satisfy user specified requirements.

Knowledge Transfer & User Training

To ensure that end user is well train and having know-how to operate the system to resolve their problem and streamline the process.

Process Improvement

To use various methodologies to analyse the procedures to identify areas where we still can improve accuracy, effectiveness, efficiency and redesign the processes to realize the improvements

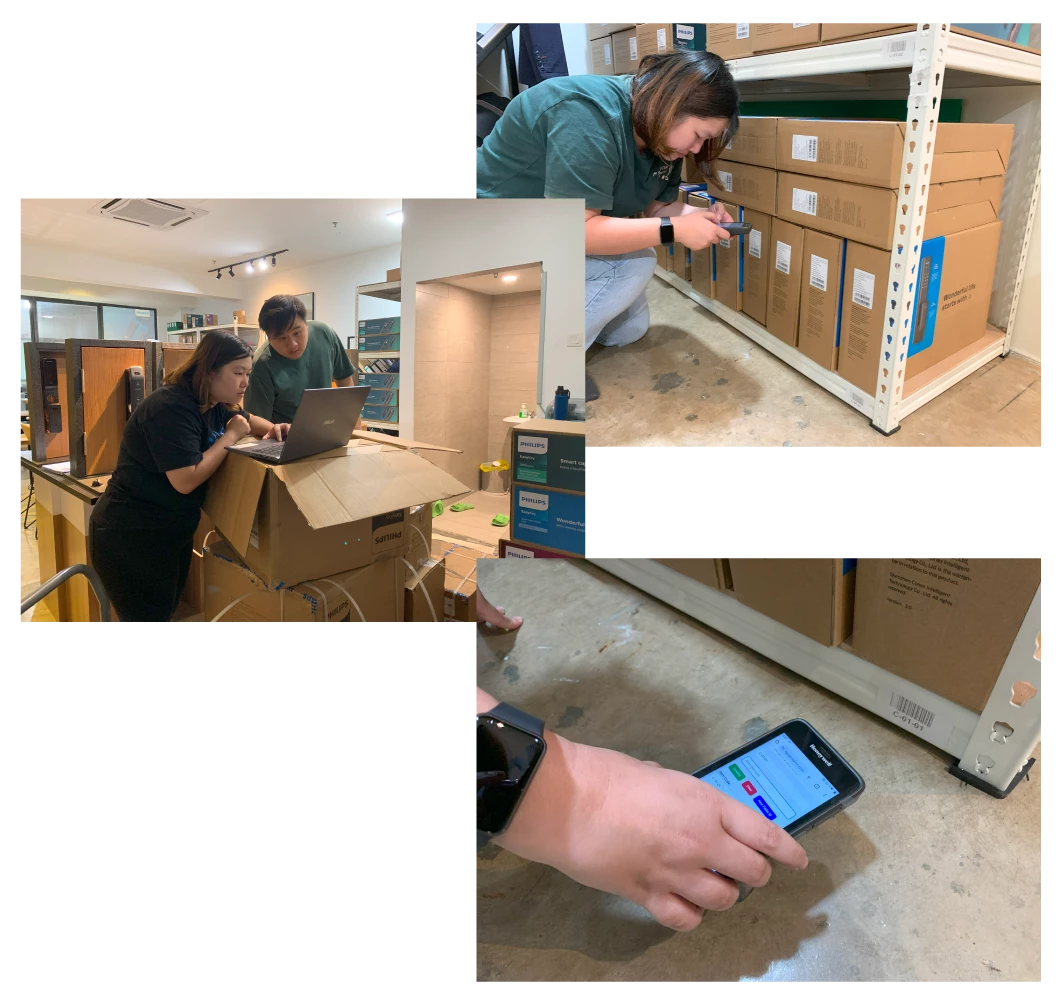

Warehouse Implementation & Experience

• A single system environment to manage multiple warehouse in different physical location but system is capable to handle multiple principal per warehouse with different process flow & stock control. Inventory team only access to a single system to retrieve multiple warehouse & principal on hand stock balance. • A consolidate multiple warehouse & multiple principal warehouse operation dashboard for management supervision, monitor & control. Warehouse manager can plan ahead to increase productivity as well as efficiency. • Enforce standard operation procedure (SOP) across all of the warehouses. Operation team in different warehouse is trained up to follow the same SOP. • Management can retrieve a consolidate report by multiple warehouse.

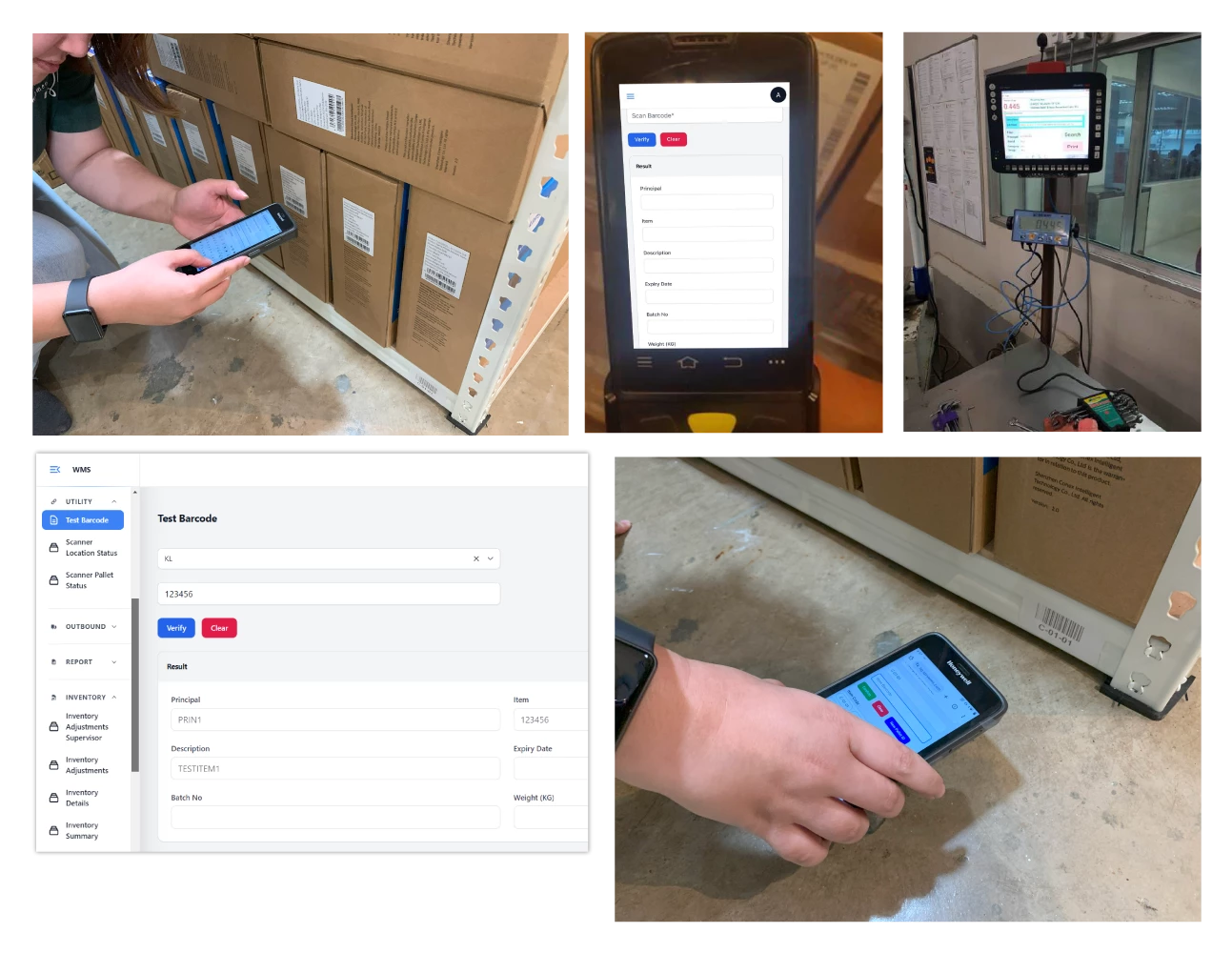

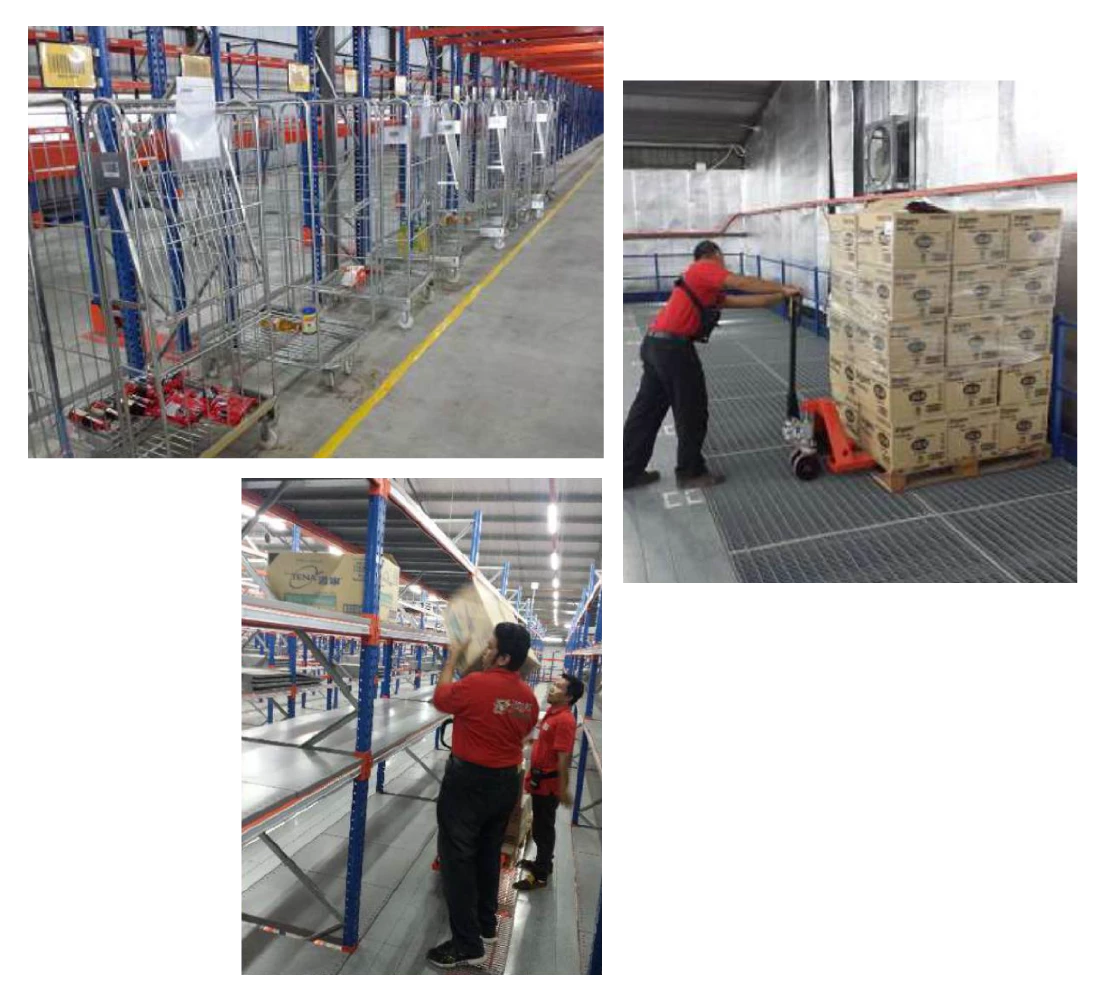

Cold Chain Warehouse Implementation & Experience

• System is capable to manage several temperature such as freezer, chiller, air cond & ambient. Picking list is split by room temperature. • An enhanced version of barcode module that can recognized/decode GS-1 128 barcode format with weight, expiry date or batch number. System is able to handle multiple type of barcode format from different oversea supplier. • Integrated digital scale to system for re-weight/re-packing process and generate a new barcode label with weight information.

Distribution Centre Implementation & Experience

• Implemented consolidate picking by route to reduce picker travel/walking time, reduce material handling equipment (lift truck/forklift) usage to increase picking efficiency. • Outlet across Malaysia access to WMS ordering web portal to place transfer order/sales order for outlet stock replenishment. To reduce communication error and paperless for ordering. Warehouse manager is able to arrange for order picking immediately & plan for order delivery by next day. • Management is able to measure warehouse delivery performance and analyse sales performance by outlet.

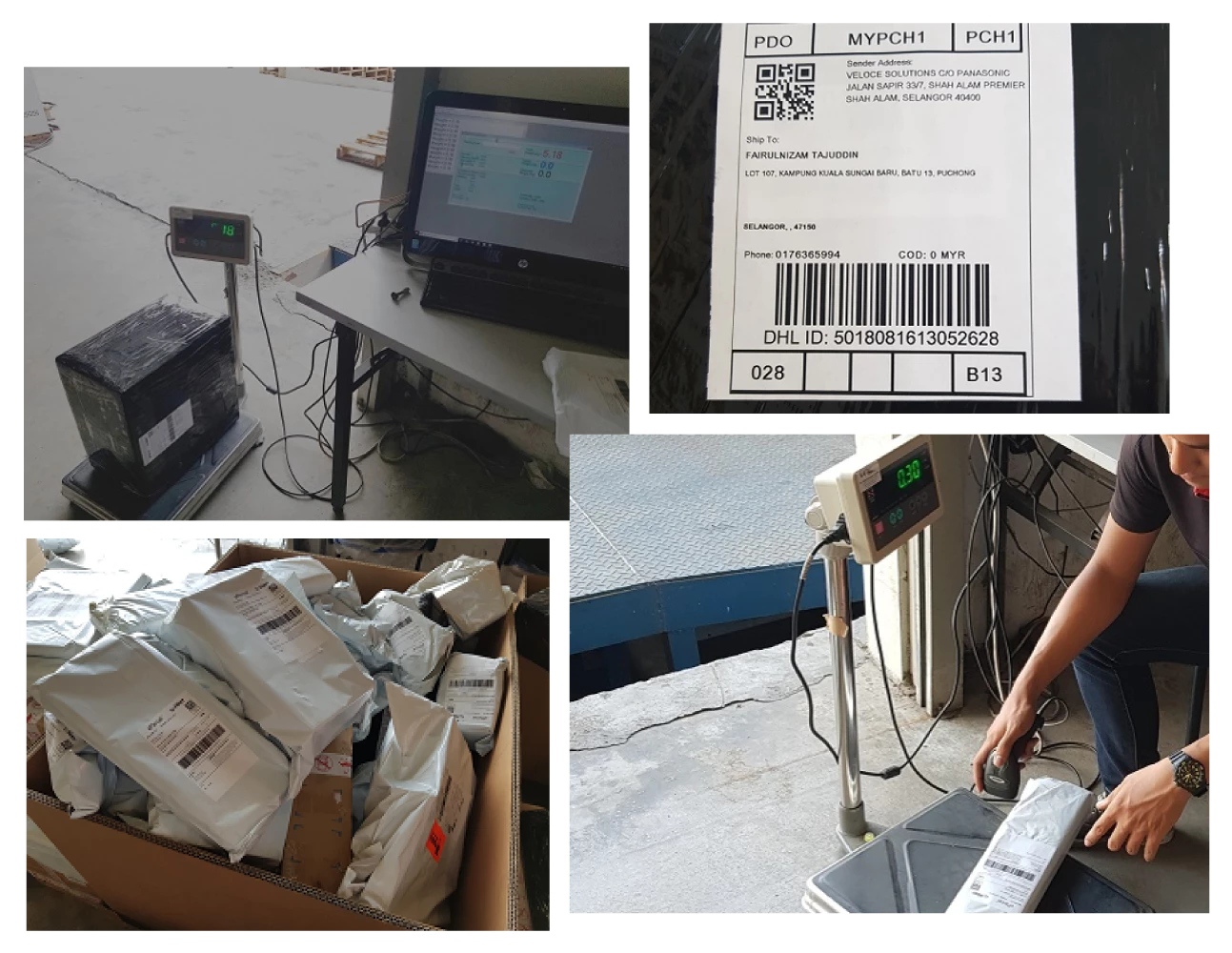

E-Com & Parcel Implementation & Experience

• Download sales order from e-com platform automatically via API (Application Programming Interface). • WMS is connected to last miles provider such as DHL, Ninja Van as well as oversea last miles provider to generate shipping label/consignment note. • End user is able to login to parcel system to upload shipment & generate shipping label/consignment note.